Self-cleaning filters are highly effective tools in the treatment of whey, a by-product of the dairy industry rich in proteins, lactose, and other nutrients. The main objective of applying these filters is to improve the efficiency of the filtration process, reducing operating costs and increasing the quality of the final product.

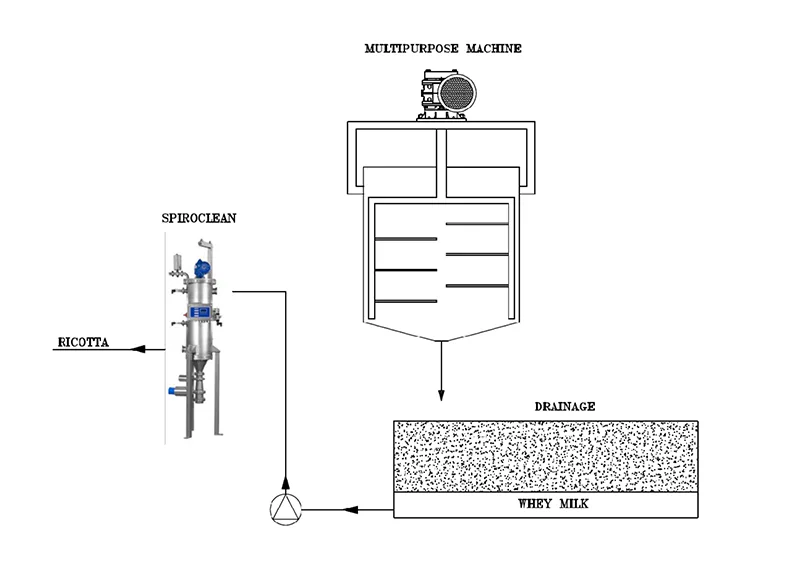

WHEY FILTRATION FOR RICOTTA PRODUCTION

Filtration of the whey sent to ricotta production. The filtration of whey intended for ricotta production is an essential step to obtain a high-quality product. Whey is the main by-product of cheesemaking, and to transform it into ricotta, it is necessary to prepare it adequately. Filtration is one of the first steps, as it eliminates impurities and unwanted particles, ensuring that the final product is clean and compliant with food standards.

Benefits

• Removal of solid impurities: Small residues of curd, fats, and other suspended particles must be eliminated to avoid defects in the texture of the ricotta.

• Protection of equipment: Filtration prevents clogging of the heating systems and heat exchangers used for whey coagulation..

• Improvement of ricotta quality: Filtered whey guarantees greater homogeneity and a cleaner taste in the final product.

WHEY FILTRATION FOR UF MEMBRANE PROTECTION

Filtering whey before sending it to an ultrafiltration (UF) or reverse osmosis (RO) plant is a critical step to ensure membrane efficiency and longevity. These plants are designed to concentrate specific whey fractions, such as proteins, lactose, and salts, but are highly sensitive to impurities and solid particles.

Benefits

• Membrane Protection: Removes solid particles, fats, and microorganisms that can cause clogging, fouling, or premature membrane deterioration.

• Product Quality Optimization: Ensures that the whey sent to UF or RO is free of impurities that could affect the characteristics of the concentrated product.

• Operating Cost Reduction: Lower membrane cleaning frequency and increased operational lifespan.

PRE-FREEZING/POST-FREEZING MILK FILTRATION

Freezing milk (cow, buffalo, and sheep) is carried out to achieve long-term preservation of the product and to use it during periods when the animal produces less.

Before freezing and after thawing, the milk is filtered.

Benefits

• Removal of physical impurities : During milk thawing, ice crystals or aggregates of fats and proteins can form, compromising the homogeneity of the milk. Filtration eliminates these particles, improving the consistency and quality of the milk for subsequent processing.

• Restoration of homogeneity: Freezing can cause the separation of the liquid and fat phases of milk, leading to an unstable emulsion. Filtration, especially when combined with gentle agitation, helps to remix the components, improving the uniformity of the milk.

• Protection of downstream equipment: Impurities and aggregates in the milk can clog or damage machinery such as pasteurizers, homogenizers, or centrifuges. Filtration removes solid particles and agglomerates, protecting the equipment and reducing maintenance costs.

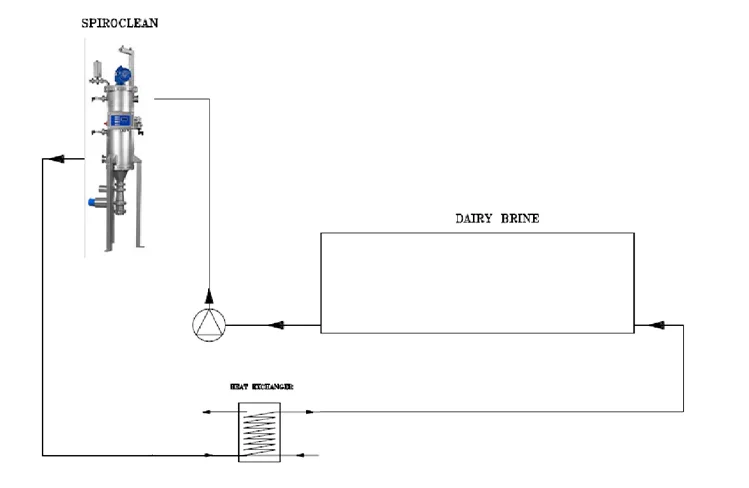

MOZZARELLA FIRMING WATER FILTRATION

Filtering the water used to cool and firm mozzarella is crucial for its recovery and reuse within dairy production. This process water, generated during the mozzarella cooling and firming stages, contains organic matter, fats, soluble proteins, and salts, which can affect its subsequent reuse and treatment.

Benefits

• Water Reuse/Recycling/Cooling Water Recycling: Filtration allows the purification of cooling water, making it suitable for reuse within the same production cycle.

• Recovery of Usable/Valuable Components/Resource Recovery: Soluble proteins, fats, and other organic compounds present in the cooling water can be recovered for secondary uses (e.g., for the production of biogas or fertilizers).

• Product Quality Improvement/Enhanced Product Quality/Preservation of Product Quality and Flavor: Clean cooling water prevents contamination or alteration of the mozzarella, preserving its quality and flavor.